Whispering Skies Observatory North Wall Transformation: Storage, Work Surface, and Under-Cabinet Lighting!

Date: Dec 28, 2025

Revision 1-14-26 (added companion video)

After running the observatory with temporary tables for months, I finally built the north wall exactly the way I originally intended: durable metal cabinets, a continuous laminate work surface, a dedicated computer “knee hole,” and lighting that makes the whole space feel finished.

Table of Contents Show (Click on lines to navigate)

Earlier Posts in the Observatory Series

I have been thinking about building an observatory for a while now. Below are previous posts that have led up to where I am today.

Whispering Skies Observatory Update for October 2025 Oct 2025

Whispering Skies Observatory: Making the Sign! Oct 2025

Whispering Skies Observatory: Drainage and Lawn Restoration July 2025

Whispering Skies Observatory: Construction Completed! June 2025

Whispering Skies Observatory: Construction Completed - Drone View of Results! April 2025

Whispering Skies Observatory: Installing Piers and Scopes! April 2025

Whispering Skies Observatory Update: Siding and Trim! March 2025

Whispering Skies Observatory: Developing a Computer and Networking Strategy! Jan 2025

Naming Your Observatory Jan 2025

Observatory Update: Powering Up the Observatory! Dec 2024

Observatory Update: Roughing In the Electric and Pouring the Slab Floor! Dec 2024

Observatory Update: Building the Structure! Nov 2024

Observatory Update: Laying the Foundation Nov 2024

Observatory Update: Custom Telescope Piers Part 3 - Painted and Complete! Sept 2024

Observatory Project: Breaking Ground! Excavation Complete! Sept 2024

Observatory Project: A Final Update Before We Break Ground! Aug 2024

Observatory Project: Opening The Roof! Aug 2024

Observatory Project: Final Roof Track System Hardware Selection July 2024

Observatory Project: Designing Custom Steel Piers - Part I June 2024

Observatory Project: Galvanic Corrosion and a Change in Track Selection! June 2024

Observatory Update: Designing the Roll-Off-Roof Track System! May 2024

The Move is Complete, Now Pivoting to the Observatory Project! April 2024

An Observatory Project Update: Success! We Just Bought A Property and Will Be Moving! Nov 2023

An Observatory Project Update - One Year In Feb 2023

Goals for my Observatory Project March 2022

Video Companion

I have a companion video to this post on my YouTube Channel, that can be seen below:

Original Concept

My original concept was for an observatory that measured 16 feet by 16 feet.

However, early in the process, I changed this dimension by adding another 4 feet to the observatory's north-south direction. The whole idea of making this addition was to create space for a countertop, some base cabinets, and some wall cabinets.

My thinking was that on the right-hand side of the building, I would have an area with a knee hole where I could place a computer screen and keyboard, and that's where I would work with the telescopes and control the observatory. While each pier has its own headless microcomputer, I need to use the observatory computer screen and keyboard to remotely connect to them when I am working in the observatory. (I can also remotely connect from my astro man cave in the house)

On the other side, the left side of the building would be a project space where I could store tools, and I would have a countertop to bring telescopes and optical assemblies and work on them.

Tables

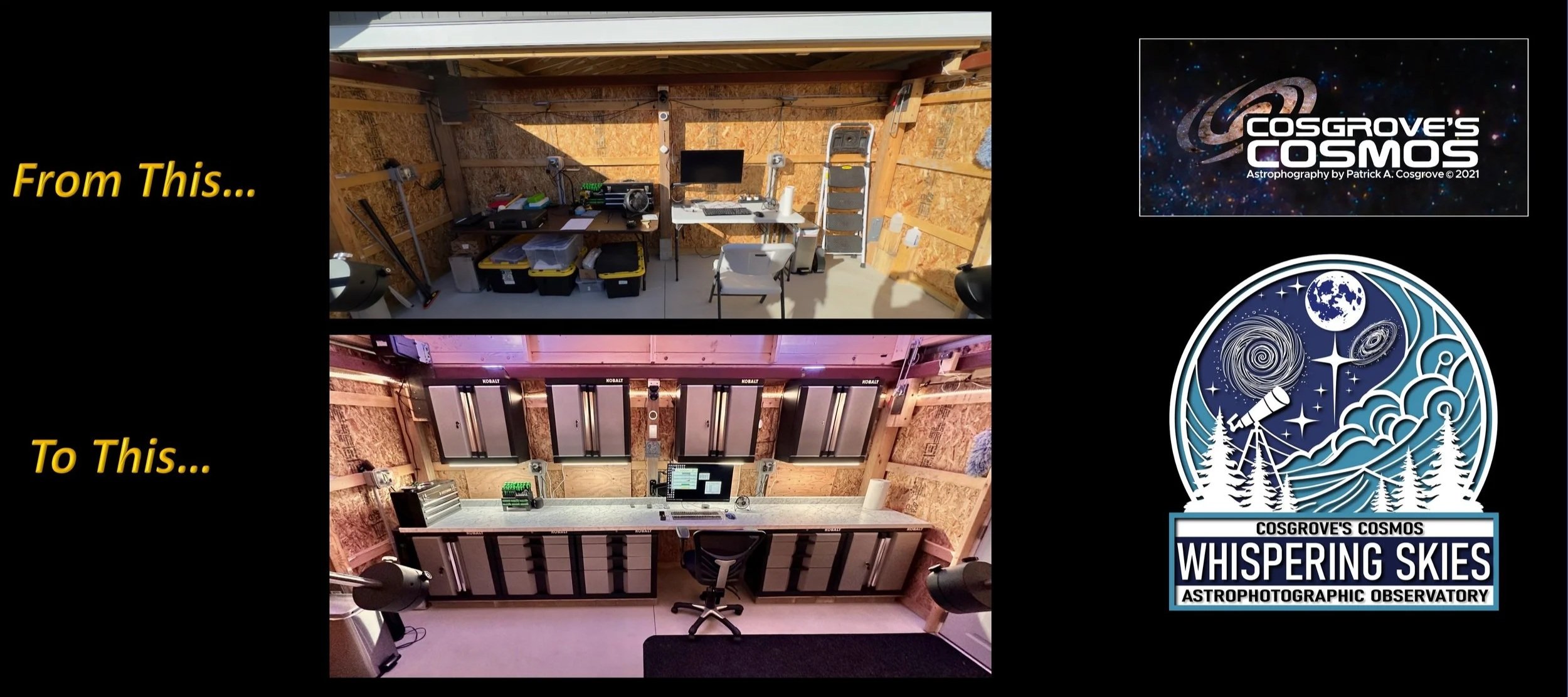

As construction neared completion and I started preparing the observatory for use, I put two tables on the North wall. The right-hand side was set up with a computer just like I had always planned. On the left side was a stronger table that I set up for tools and as a work area. Under this table, I placed some bins for storage.

For a long time, the main focus was on completing the main shell of the observatory - getting the walls up, the roof done, installing the track system, cladding the building, putting the siding on, and so forth.

Once this was done, the next step was to install and set up the telescopes so the observatory could be put into use. I mean, after all, that's why I was going through all of this trouble!

So for about eight months, all that really existed on the North wall was the two tables. But clearly, this was a situation I wanted to change.

This is how the north wall looked for the first eight months after the observatory became operational. Functional but looked pretty messy and disorganized.

A Design

I had a rough idea of what I wanted on the north wall, but no details. In late fall, I decided to get moving. I wanted to complete this last phase of the project before the snow began to fall.

Around this time, we began working with a kitchen designer to update the kitchen in the house we had just moved into.

As we talked, I asked her if she could recommend a way to get some relatively inexpensive cabinets for the observatory. So she visited the observatory, took a bunch of measurements, and said she would think about what we could do there. I shared some of my ideas with her and what I was hoping to achieve.

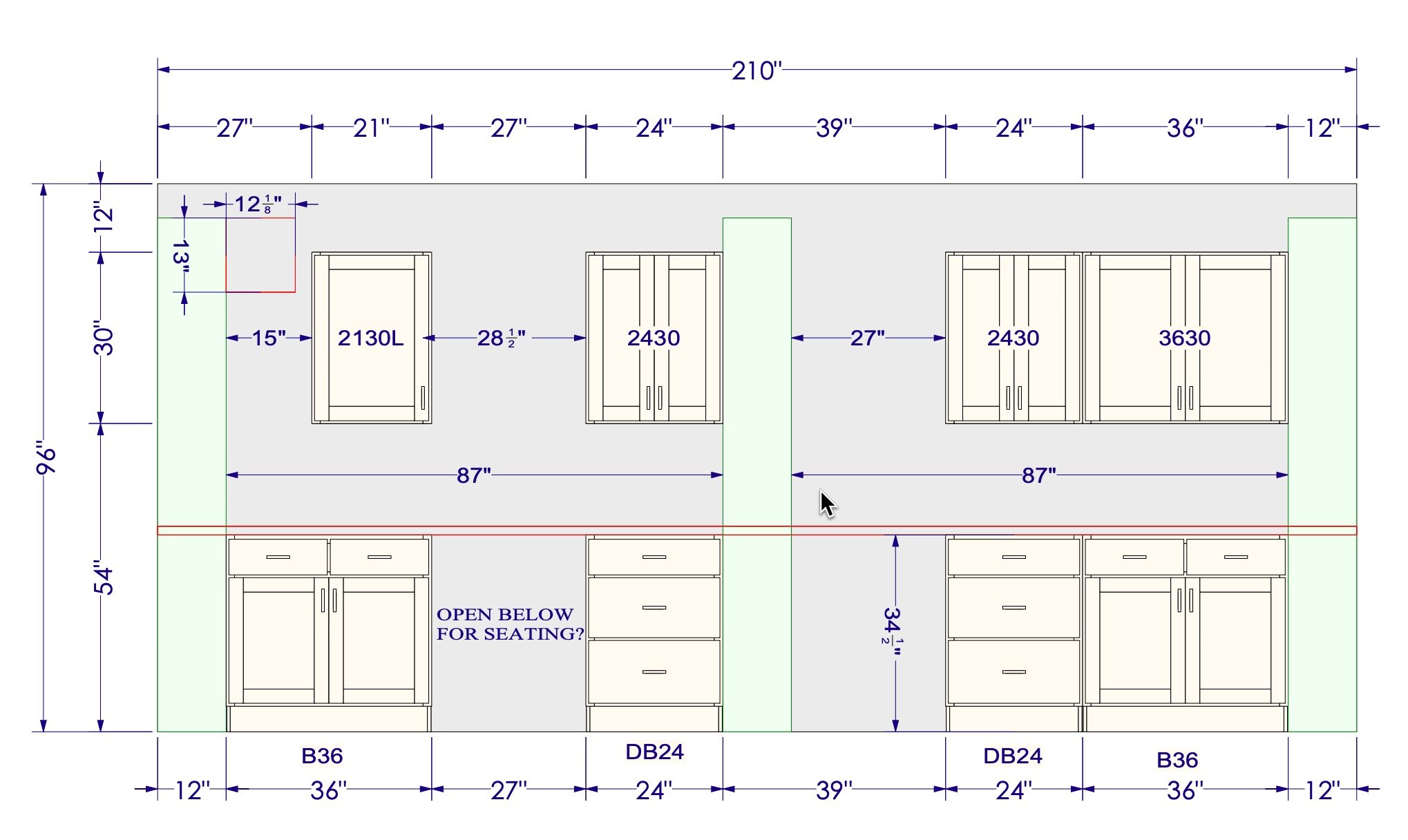

A little while later, she came back with a design that was pretty close to what I wanted. We went back and forth a few times, but soon I had a plan that seemed fairly reasonable.

An initial design - this was far enough along so that I could now start to price out what the cost would be for various cabinet selections.

I asked her to price a set of cabinets and a countertop that met the design specifications while remaining as cost-effective as possible. The quote came back at around $ 5,000. This is just for the cabinets! It did not include the countertop or installation. I asked for a quote for the countertop. This brought the total to over $ 7,000.

The design was good, and the cabinets were of very reasonable quality, but I was not building a kitchen - this was for an observatory. I had already overrun the observatory budget, and I was looking for a way to do this at the lowest possible cost. This was just too much.

Picking My Own Cabinets

I went online and started looking at what Home Depot had to offer. I found a line of reasonably priced finished cabinets, and the total for the cabinets and countertop would be about $3,500.

This seemed much more reasonable.

So my wife and I went into Home Depot, having set up an appointment to order all of the cabinets.

As we described what we planned to use them for, the person we were working with strongly recommended against using those cabinets for this application.

The problem was that these cabinets weren't painted - these were finished with a vinyl process that was vacuum sealed on a particle board base. Normally, this was a good way to go. However, our application had a problem: the temperature was uncontrolled, and the cabinets would expand and contract with the temperature variation. This could cause cracks in the vinyl, allowing moisture to seep through the finish. Since the wood beneath was just particleboard, it could absorb moisture, causing the finish to potentially peel off. She felt such cabinets would not last long and would not be a good use of our money.

She suggested an alternative.

Why not use unfinished cabinets? These were even more affordable, and the fronts were made of nice Birch hardwood, while the rest of the cabinet was made of particleboard. Since these cabinets had to be finished, there was no reason you couldn't finish and seal the particleboard and wood, creating something that would withstand the temperature ranges we would encounter in the observatory.

I pushed back on this idea because it was already late in the year, and the outside temperatures were freezing. I couldn't imagine painting and sealing these cabinets when the temperature was too low for any sealant, paint, or finish to cure properly.

Her response was to suggest a professional painter; they could pick up the cabinets and bring them into their heated shops. They could spray them to seal the cabinets and give the wood a good finish. Once they were cured, I would return them and install them. This sounds like a pretty good idea!

I priced these cabinets, and the cost would be around $ 2,200. So if the finishing cost wasn't all that high, this might work out just fine.

I began calling paint shops in the area to gauge the cost.

I quickly found that if I wanted such bulky items picked up, transported to their paint shop, the entire cabinet sealed (not just the fronts), and then delivered back, I was looking at a cost well over $3000. So once again, I had a cost that was much higher than I wanted to spend, and I didn't have a viable path forward.

A New Direction and a Strange Collaborator

At this point, I was really at a loss.

I'm a tech geek, and recently I began to play with ChatGPT.

So I had this crazy idea: why not just describe my application and ask ChatGPT for something that would fit my budget, be suitable for an environment where the temperature isn't controlled, and might be exposed to moisture in the form of dew.

ChatGPT came back with a surprising idea. Why not get a powder-coated tool chest and garage cabinets?

These were designed for spaces where temperature is not controlled, and the powder-coated finishes resist moisture.

These could be easily modified and used as the foundation of a cabinet system.

Here was ChatGPT’s response if interested:

Cost-Effective Moisture-Resistant Cabinetry for Observatory Wall

Overview & Requirements

A 190-inch-wide north wall in a residential observatory will be outfitted with cabinetry and countertops, split into two 8-foot sections: an eastern 8 ft computer workstation (with seating space) and a western 8 ft telescope toolbench. Key requirements include:

• Moisture and Thermal Resistance: Materials must withstand humidity and temperature swings without warping or rotting (important in unconditioned observatory environments). Avoid unsealed particleboard or other materials prone to moisture damage . Powder-coated metals, plastics (HDPE, PVC), or sealed woods are preferred.

• Durability & Low Maintenance: Surfaces and hardware should handle heavy use and require minimal upkeep (e.g. rust-resistant coatings, sealed finishes). Steel cabinets with quality powder coat or polymer cabinets are ideal; untreated wood or flimsy plastic is not .

• Pre-Assembled/Light Assembly: Cabinets/drawers should come assembled or mostly assembled. The user wants to avoid complex builds (especially drawer construction). Modular units or pre-welded cabinets are favored.

• Budget: All-in budget is ~$3,000 (including cabinetry, countertops, hardware, finishes, and any shipping). This suggests cost-effective, off-the-shelf solutions or used/refurbished deals rather than custom high-end millwork. High-end kitchen cabinet systems are to be avoided.

• Configuration: Under-counter storage (drawers, cabinets) along both 8 ft sections. The computer desk (east side) should have a knee-hole for seating (e.g. open space in the middle of that 8 ft span), whereas the tool bench (west side) can be fully cabinet-based for maximum storage. Above the counter, the user desires wall-mounted cabinets or shelving for additional storage. The total vertical space is limited to ~80″ height, so tall cabinets must fit below this.

• Continuous Countertop Preference: Ideally use a continuous counter surface across each 8 ft section (or at most two segments spanning the 15′-10″ wall). Counters should be moisture-resistant (or sealed) and rugged (withstand tool use, equipment, and possibly occasional dew exposure).

Key Challenge: Balancing moisture resistance and durability with cost. Standard interior cabinets (especially cheap particleboard units) may not tolerate observatory humidity . We should consider garage/workshop-grade cabinets, outdoor-rated cabinetry, or industrial surplus as alternatives to conventional kitchen cabinets.

Below, we evaluate several solution categories with examples, then provide a comparison table of top candidates.

Steel Garage/Workshop Cabinet Systems

Leveraging garage storage cabinet systems is a strong option. These systems are designed for unconditioned spaces (garages) and thus built to handle humidity, temperature swings, and rough use. They typically feature powder-coated steel construction, which offers excellent moisture resistance (no swelling or rot, and good rust protection if the finish is high-quality)  . Many come pre-assembled (welded), requiring only anchoring to walls or minor assembly, and include integrated countertops or worktops.

Examples:

• Husky Welded Garage Cabinet Sets (Home Depot): Husky offers both “Regular Duty” (24-gauge steel) and “Heavy Duty” (20-gauge) cabinet packages. For example, the Husky 8-Piece Regular Duty Welded Steel Storage System spans 133″ W x 75″ H x 19.6″ D , which includes two tall lockers, two base cabinets, an 84″ solid wood worktop, and three wall cabinets. It comes pre-assembled for easy installation and is engineered to endure garage conditions (24-ga steel that “stands up to daily use, harsh temperatures and humidity,” with a scratch-resistant powdercoat) . At $2,295 new , this set would cover most of the wall’s storage needs within budget. One could install one tall cabinet at the far west end and one at the far east end of the wall (each 75″ high, below the 80″ limit), and use the 7-foot workbench section in between as the central counter/storage. For the observatory’s layout, the 84″ wood top and base cabinets can form the tool bench section, while the knee-space computer desk could be created by omitting one base cabinet under part of the top. (The wood top should be sealed with polyurethane or epoxy for added moisture protection, or replaced with a more water-resistant top). Wall cabinets from the set (matte black steel) can be mounted above for enclosed overhead storage. This Husky system provides a cohesive, professional look and is built for longevity. (Note: The Heavy Duty Husky set is larger – 156″ W x 81″ H x 24″ D  – with thicker steel and a Line-X coated worktop, but its 81″ height slightly exceeds the observatory’s 80″ limit and the cost ($3,300 ) is above budget.)

• NewAge Products “Bold 3.0” Garage Cabinets: NewAge’s Bold Series is another 24-ga steel, powder-coated system that’s popular for garages. A Bold Series 6-piece set covers about 12 feet (144″) width x 76.75″ height x 18″ depth , which would fit under the height cap. For example, one configuration includes two multi-use lockers (tall cabinets), three wall cabinets, and a base cabinet with a 62″ stainless steel or bamboo worktop, all for roughly $2,100–$2,400 (prices vary by finish and retailer)  . These cabinets come fully welded (no assembly) and are powder-coated for corrosion resistance. In an observatory, the lockers could be placed at ends or one per 8-ft section, and the base+worktop segment can serve as a desk or bench. One consideration: the standard Bold set worktops are only 18″ deep (to match cabinet depth), which is a bit shallow for a computer desk or toolbench (typical counters are ~24″ deep). This can be solved by installing a deeper countertop over the base cabinets (e.g. a 24″ countertop that overhangs the 18″ cabinets by 6″) or by pulling the base cabinets slightly forward. Despite the shallow depth, the Bold series offers great durability in a damp environment – powder-coated steel frames and stainless/bamboo worktops are highly moisture-tolerant. The cost is competitive (often on sale around $2,200  for a set covering most of the wall), leaving budget room for adding a custom deeper top or extra components.

• Gladiator GarageWorks Modular Components: Gladiator (by Whirlpool) produces garage cabinetry (the “Premier” line is heavy-duty steel). For instance, the Gladiator 8 ft Hardwood Workbench (96″ x 25″ top) paired with Modular GearDrawer cabinets (each ~28″ W, 25″ D) can create a robust workbench with storage. Three Gladiator modular base units can fit under an 8′ top. As a scenario, one could use two drawer cabinets with a knee space in center for the computer desk, and three cabinets across for the tool side. Gladiator’s steel cabinets are pre-assembled and built for garage environments (thick powder coat; 25″ depth gives a full work surface). However, Gladiator components purchased a la carte can be pricey: e.g. a single 5-drawer GearDrawer is often ~$700. Pre-configured sets (e.g. an 8-foot workbench plus two base cabinets and some upper cabinets) sometimes are available as packages in the $2,000–$3,000 range. This route guarantees moisture and rust resistance but needs careful cost management.

Pros (Garage Cabinet Systems): Very durable steel construction, high load capacities, built to handle humidity , largely pre-assembled, integrated work surfaces, locks for equipment security, and a clean, professional look. Many sets include wall cabinets or shelves for above-counter storage, matching the base units. These systems often come with lifetime or 10+ year warranties due to their intended rough use.

Cons: Upfront cost can consume most of the budget (though still within $3k for moderate sets). Depth of some systems is 18–20″ which may require a custom deeper top for comfortable use. The included countertops (wood or bamboo) should be sealed against moisture (or could be swapped for a laminate or metal top if desired). Also, large steel components are heavy; factor in shipping or freight delivery (some retailers offer free delivery or in-store pickup).

Notable Candidates: Husky 8-Piece Regular Duty (133″ W) – ~$2,295, steel + wood top  ; NewAge Bold Series 6-Piece (144″ W) – ~$2,150 on sale ; Gladiator modular with 8′ bench – est. ~$2,500 for 2-3 base cabinets + top + a couple wall cabinets. Each of these provides a mostly metal, moisture-proof storage solution covering 11–12+ feet of the wall. The remaining portion of the 15.8′ wall (if any) could be filled with either a small additional cabinet or shelving. The two 8-ft sections can be distinguished by configuring one with an open knee space and the other fully enclosed.

Here is a Husky tool chest. Now imagine removing the wheels and the top - it becomes a base cabinet!

Of course, some of these tool chests were on wheels, and many were not deep enough to accommodate a traditional countertop. They typically measure 18-20 inches deep, while the traditional countertop is about 25 inches deep.

ChatGPT suggested I buy these cabinets, remove the wheels, and mount them on the floor, with the fronts 25 inches from the north wall. A wall-mounted ledger board could support the countertop's back, while the front would rest on the steel cabinetry. In this way, a traditional countertop could be installed. Of course, there would be some empty space between the wall and the back of the cabinets, but so what?

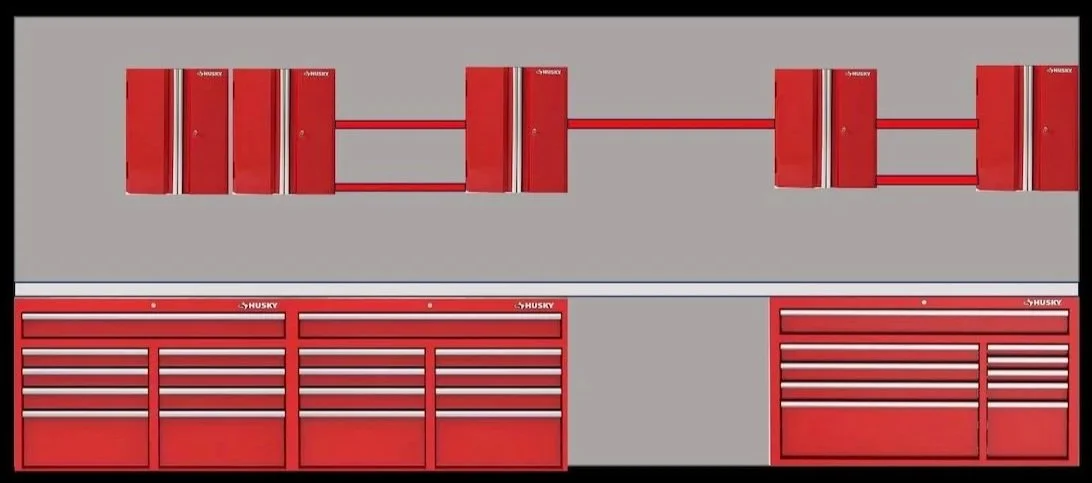

This was a very interesting idea. ChatGPT suggested I explore the Husky Line of Tool Carts at Home Depot. These looked promising, but I had two problems with them.

First, the drawers were very wide. If I put one on each side of the knee hole, the drawers in the desk area would be very wide and awkward to use.

Another problem was the color. To match the wall and base cabinets, my only choices were black and red. I played with a design using the red:

But this struck me as being too car-shop-like.

So I started looking for some alternatives.

I found small cabinets at Lowe’s branded as Kobalt. They came in two basic configurations: either a four-drawer unit or a two-door unit. The product line also included a matching set of wall cabinets. The case had a black frame, gray doors, and drawers that looked great.

The cabinets were only 28 inches wide, so the drawers would not be as awkward.

Also, being smaller, it would be much easier for me to manhandle.

The two-door base cabinet.

The four-drawer base cabinet.

The two-door wall cabinet.

Injecting this option into my ChatGPT discussion met with approval. ChatGPT thought they would work even better.

ChatGPT designed a wall of cabinets based on my specifications, and it looked like it would work out pretty well.

Here was an early mockup of how I would use these cabinets in the observatory. Originally, I was thinking about putting shelves between the wall cabinets.

North Wall Cabinets & Counters — Specs at a Glance

- Observatory footprint: 16'×16' original, extended +4' in the north–south direction to create this storage/work zone.

- Base cabinets: 5 total (Kobalt metal garage cabinets).

- Wall cabinets: 4 total; mounted using 3/4" plywood backers (28" wide × 48" tall).

- Cabinet module width: 28".

- Countertops: two 8' laminated sections (marbled white); one section trimmed to final length on install.

- Knee hole span: 38" (reinforced with a 2"×36"×1/8" steel bar under the front edge).

- Ledger support: 2×6 ledger with GRK screws; angle irons at 16" centers (12" at the knee hole).

- Sealing: oil-based polyurethane, two heavy coats on the underside of the countertops (and the plywood bases).

Cost Snapshot (from this build)

| Option / Item | What happened | Cost stated in post |

|---|---|---|

| Kitchen-designer cabinet plan | Good design, but too expensive for an observatory application. | ~$5,000 cabinets only; $7,000+ with countertop |

| Home Depot finished cabinets | Rejected due to temperature swings + vinyl finish over particleboard concerns. | ~$3,500 (cabinets + countertop) |

| Lowe’s “Pro” project (final path) | Kobalt cabinets + two 8' laminate tops; earned a Pro discount. | $2,500 quote; $250 discount (10%) |

ChatGPT still makes mistakes.

I discovered that the countertop height wouldn't align with the cabinets because the cabinet height ChatGPT used was based on a spec that still had the wheels mounted on the bottom. I would be removing these wheels, so the measurement is wrong. When I pointed this out to ChatGPT, it quickly realized its error and suggested that the best solution was to build a wooden plinth.

I had no idea what a plinth was, so I asked it to describe what it would look like and how I would build it. It assembled an elaborate design using plywood and 2x4s to create a wooden platform for the cabinets, bringing them to the desired height. Great!

I then asked ChatGPT to create a materials list and use Home Depot as a reference to develop a budget for building these plinths.

The budget came out to be about $500! This dramatically raised my spending on this project!

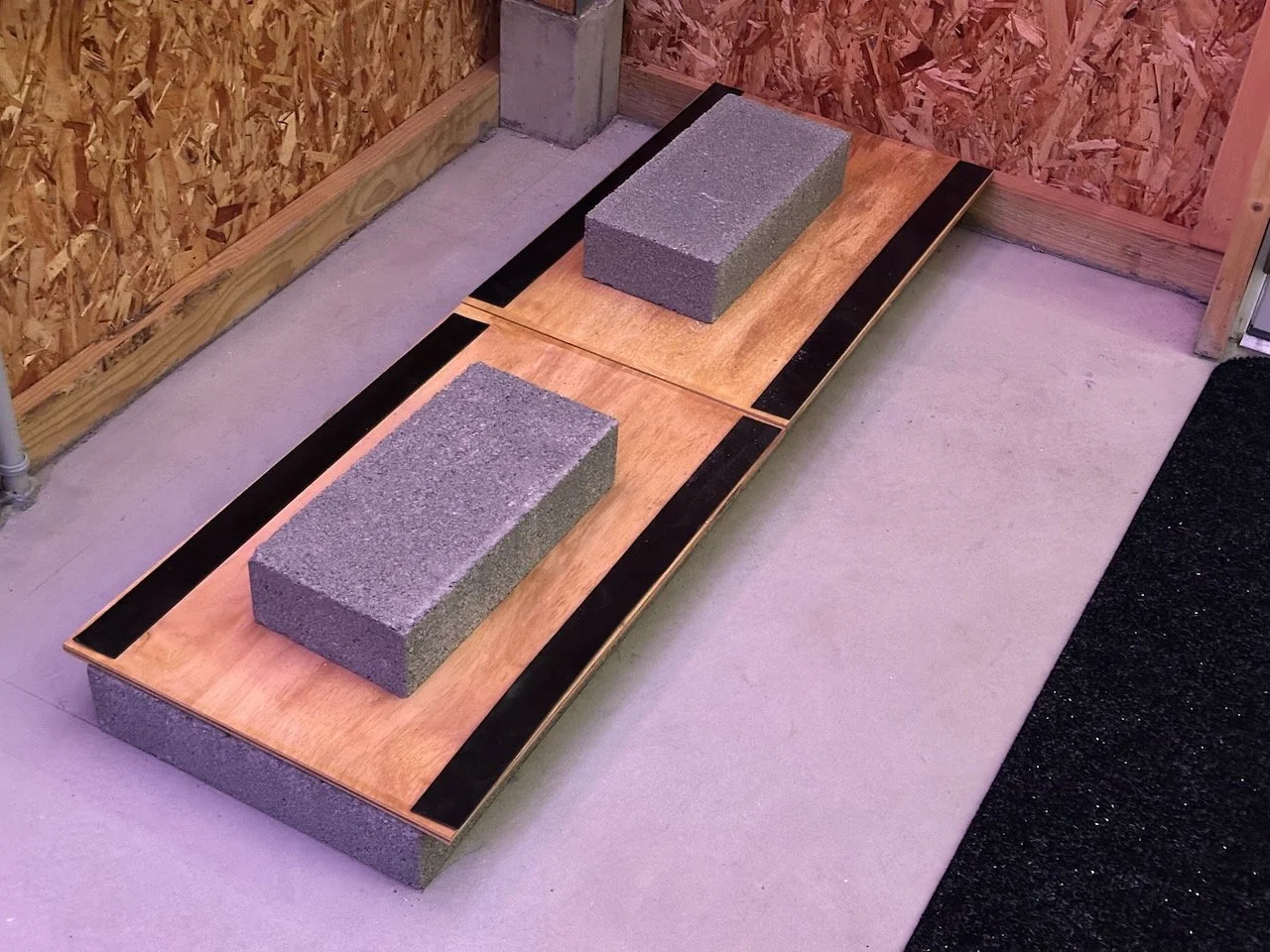

I pointed this out to ChatGPT, and 'he' replied, "Well, if that's the case, then why don't we just use concrete blocks to lay down a base and a plywood plate on top of that?" This would yield the desired heights, and the blocks are only $2.00 each.

A great idea! This, of course, begs the question: why would ChatGPT, if it were so smart, not have suggested this to begin with?

Placing the Order

ChatGPT also recommended getting a 'Pro' account at Lowe's. It's free and would let me place everything I need to buy into an online 'Project' and then request a quote. I did this, and the $2,500 total also earned a $250 10% discount!

I ordered the cabinets and two 8-foot sections of laminated countertops. The countertops I ordered were essentially marbled white, and the least expensive Lowe’s carried.

Here is one view of the countertop I ordered.

This shows the edge profile of the counter. The top lip would fit right over the front of the metal base cabinet.

A week later, Lowe's delivered these. Everything looked to be in great shape.

Assembly

Now that I had the cabinets, I needed to assemble them. I chose to do these in my garage as it was warmer and more spacious than the observatory.

First, I had to unbox each cabinet. These were very well packaged, but generated a lot of removed packing material.

The assembly for the drawer units involved installing the wheels. But since I did not need the wheels, I could skip this step entirely. Then I needed to remove the very nice wood tops. The laminated tops would cover these, so why leave them on? To do this, I needed to remove the top couple of drawers, then four screws.

The assembly for the two-door units was slightly more complex. Sides had to be bolted to the backs, and the tops and bottoms had to go on. Next, the shelves and doors were put on. Not really very hard - the units seemed to be well engineered and went together easily enough.

But I did run into one issue.

One of the wall cabinets has flanges welded to it, and they popped off during assembly. I checked all of the other units, and these flanges were solid.

Okay, time to call Lowe’s service! This turned out to be painless. I called an 800 number, spoke with a guy, described the problem, and they arranged an exchange: the replacement unit would be delivered, and the old one would be picked up at the same time. Just put the parts together the best I could, and they would take the pieces away. The new unit was just fine.

The assembled cabinets in my garage.

Another view.

Sealing the Countertops

The countertops were made of particleboard and needed to be sealed. I bought some oil-based polyurethane and put two heavy coats on the underside of the countertops. I taped off the edges to prevent spillover and used cardboard boxes from the cabinets to hold them in place.

I also sealed the plywood that would be placed on the blocks as the foundation.

The countertops and the plywood bases drying after having been sealed. Note the space heater. The garage is insulated and I was able to keep the temps high enough for curing only because we had a couple of days of warmer weather.

Laying out the foundations

First, I had to strip out everything from the north wall. Then, using a tape measure and a long steel rule, I marked the floor in pencil where the cement blocks would go. Then the blocks were lugged up the hill.

The north wall with all the clutter removed.

The east side cabinets laid out in pencil.

The west side cabinets laid out.

Once this was laid out, I could then put the blocks into position.

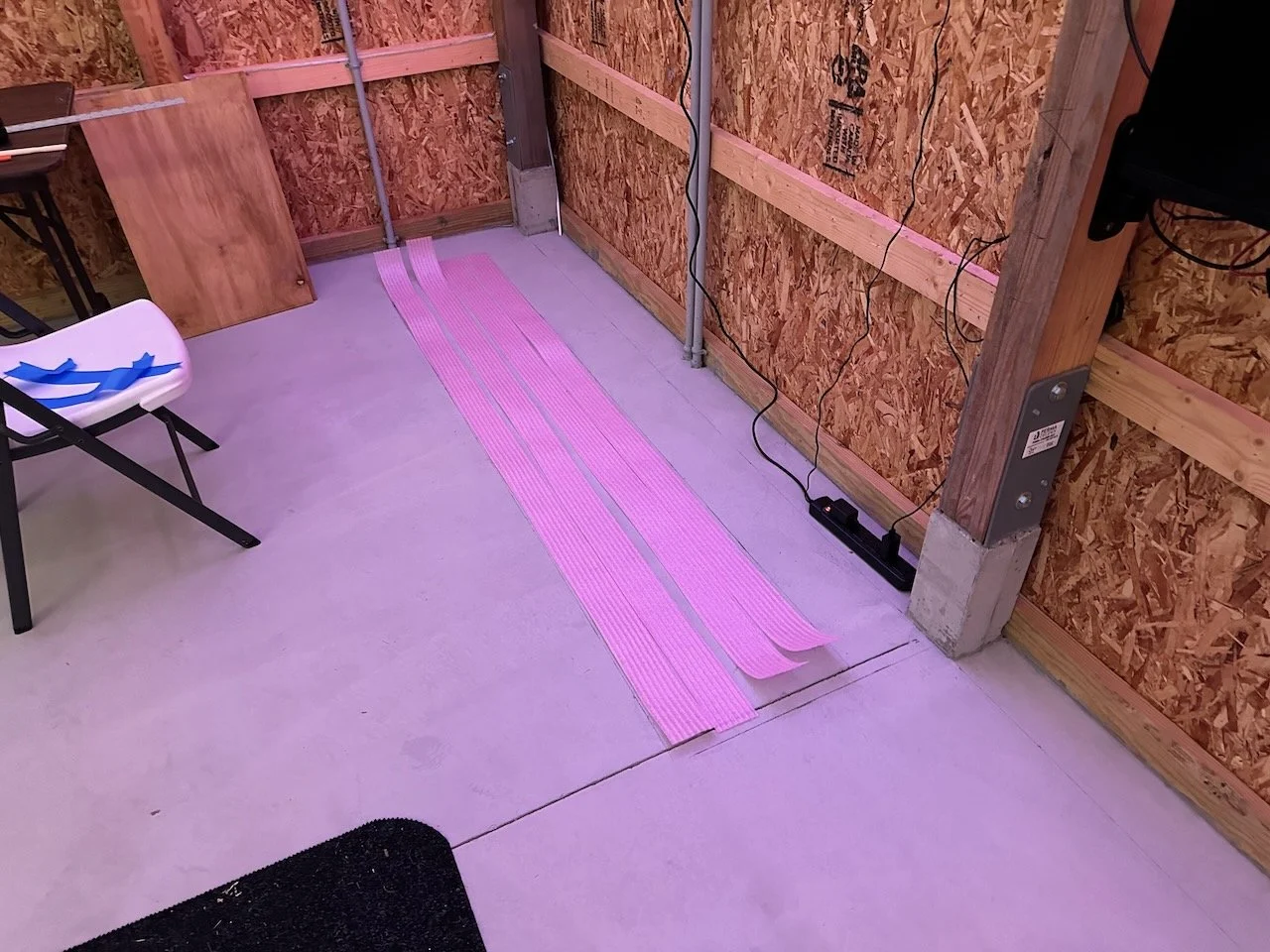

I started by laying out strips of sill seal to break a connection with the concrete floor. Then the blocks were laid, and the plywood plates were installed on top. Finally, two strips of rubber tape were applied to the plywood to prevent the cabinets from sliding.

Laying out the east side sill seal strips.

Laying out the west side sill seals.

Laying down the blocks on the east side.

Plywood foundation boards in place.

Laying out the blocks on the west side.

Now on the west side.

Showing the profile when the plywood would for the kick plate for the front of the cabinets.

The first cabinet in place so I could double check the height of these components.

The next day, I hauled one of the lighter two-door base cabinets up to the observatory and placed it on the blocks. I did this solely to precisely measure the final height. I needed this measurement to put a ledger board on the back wall.

Installing the Ledger

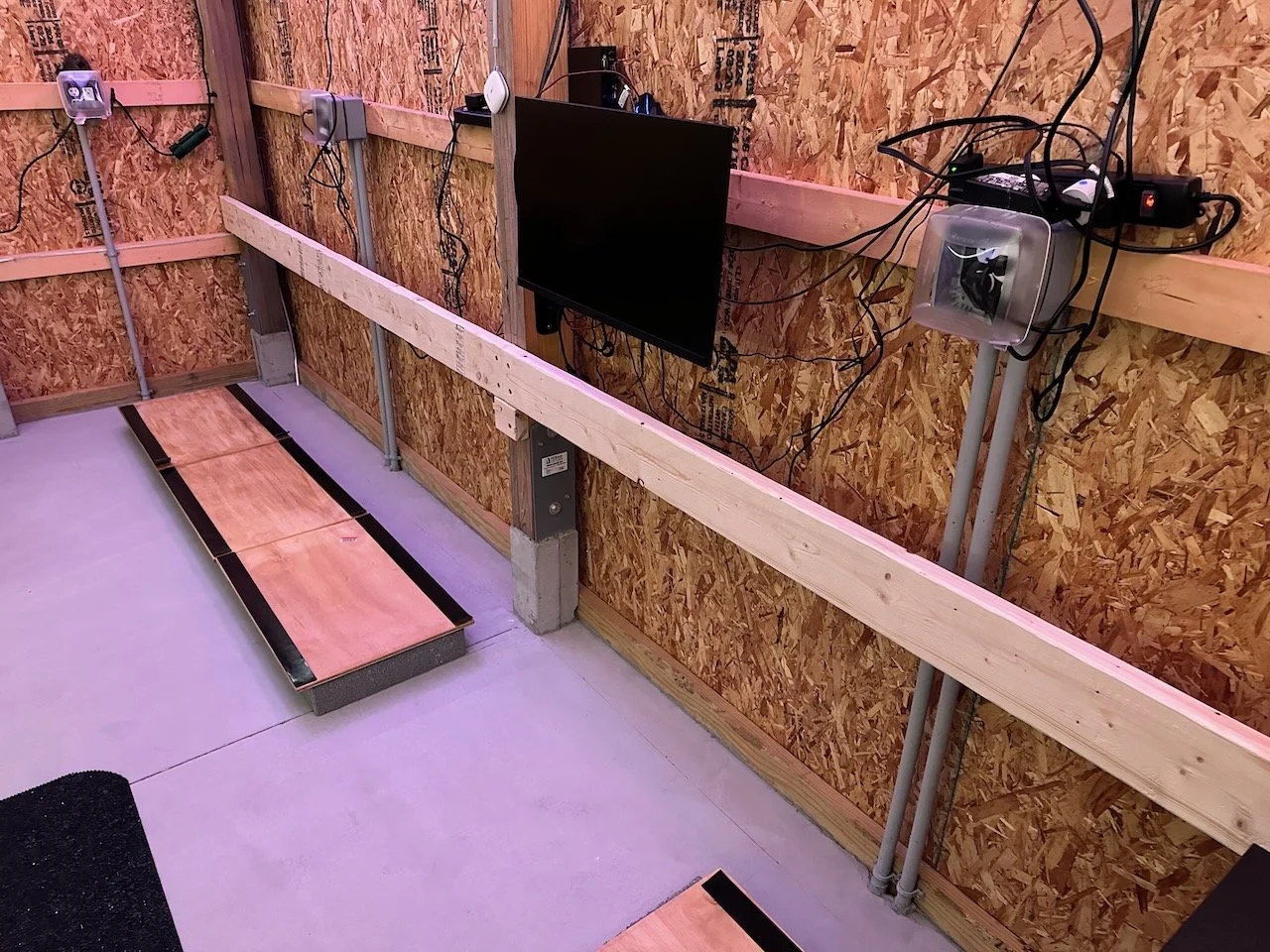

Since the observatory was built using pole-barn methods, I did not have a standard set of 2x4 studs to mount the ledger on. But I did have heavy-duty columns at the ends and in the middle. These were still roughly 8-foot sections, so I used 2x6s as the ledger board and GRK construction screws. I assumed that once I had these in place, I would have to rig some supports at least mid-ledger. But once I got them in, I was impressed with how solid this was. The use of 2x6's was a good call!

Next, I mounted metal angle irons on. These would not only better support the countertop but also provide a place to install screws to secure it in place. They were installed on 16-inch centers for most of the length except for the knee hole, where I used 12-inch centers.

When I placed the first cabinet on the plywood, I found it awkward to position both the plywood on the blocks and the cabinets on the plywood, as they all moved around.

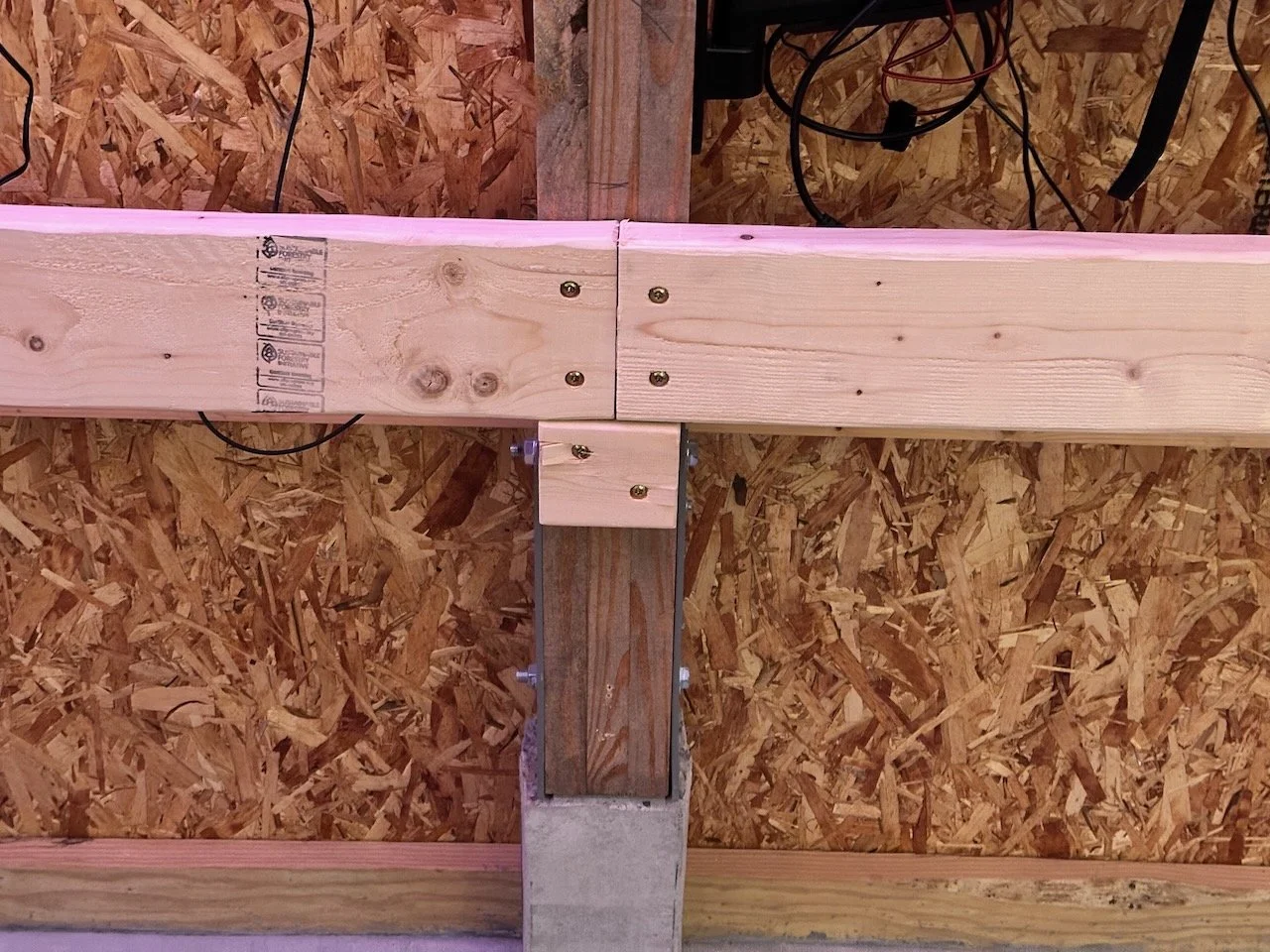

So I added some cleats at the back of the plywood, positioned so that when they were against the blocks, the cleats would be in the correct position. I added these to each plywood section, then applied lines of construction adhesive to the blocks and installed the plywood. I then put some weights on each and let them sit overnight. This would ensure we have the right position and would lock things down, making the installation of the cabinets much easier.

The installed ledger board.

The two sections met at the center column. I installed a support block under the intersection of the two boards to reinforce things.

Here you can see the angle brackets on the ledger boards and the weights on the plywood sections after construction adhesive was used.

Another view.

These are the cleats I used to ensure proper positioning on the blocks.

Another view.

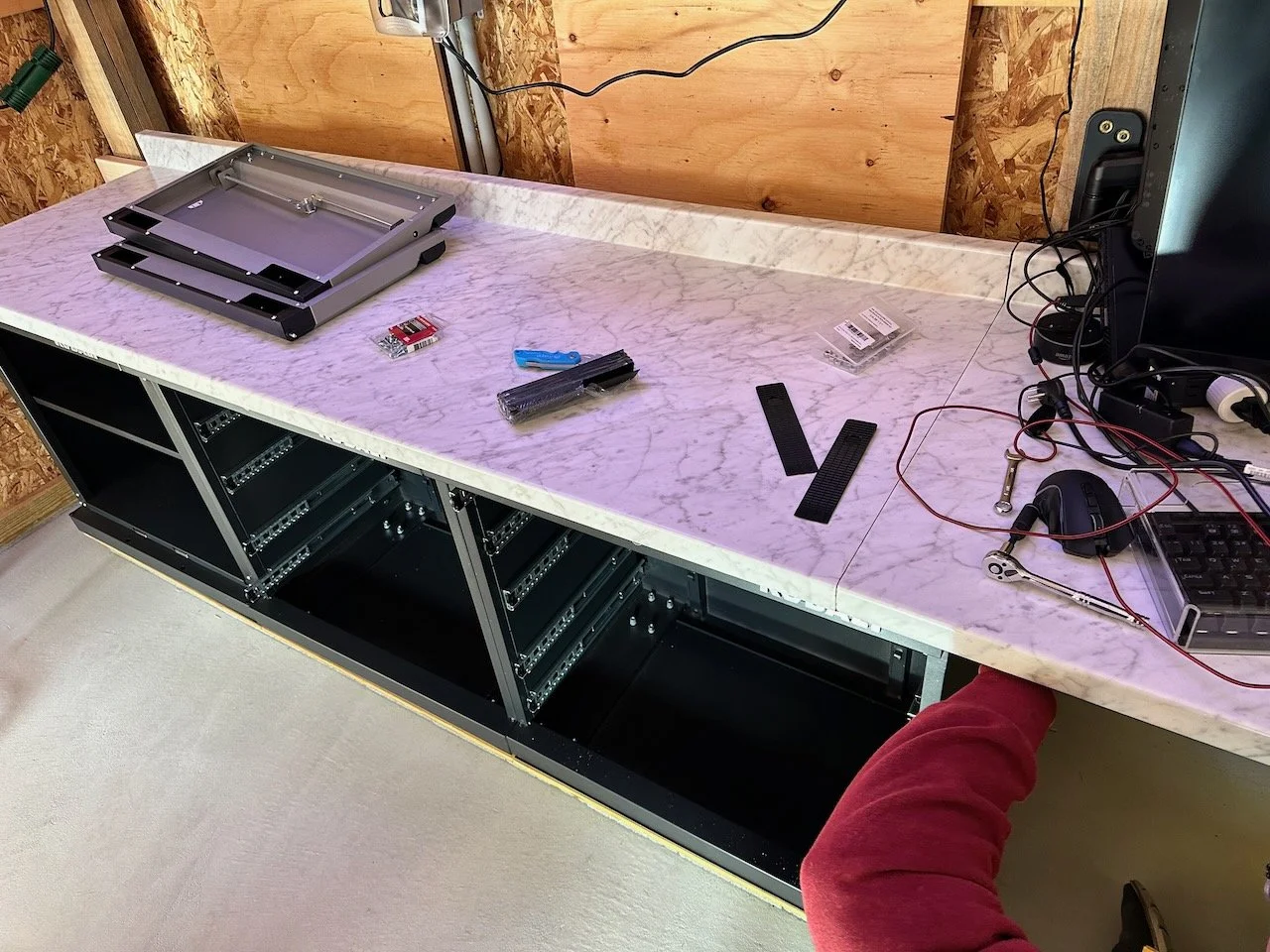

Installing the Base Units and Countertops

Now I was ready to install the base cabinets and countertops.

I had a couple of good friends (Thank you, Glenn and Gary!) come by to help, and in no time, we had the five base cabinets transported to the observatory and set in place. Next, we set the first eight-foot section of countertop on the east side! This section would span the knee hole, so I wanted to make sure the cabinets on the west side supported it.

The first section of countertop is dry-fitted into space.

With the first countertop and base units in place, I could get an accurate measure for the last section of countertop.

The other thing I wanted to do was reinforce the countertop area toward the front of the knee hole. After all, this was just particleboard spanning 38 inches. The ledger board and angle irons would provide support from the back, but there was no support or reinforcement at the front.

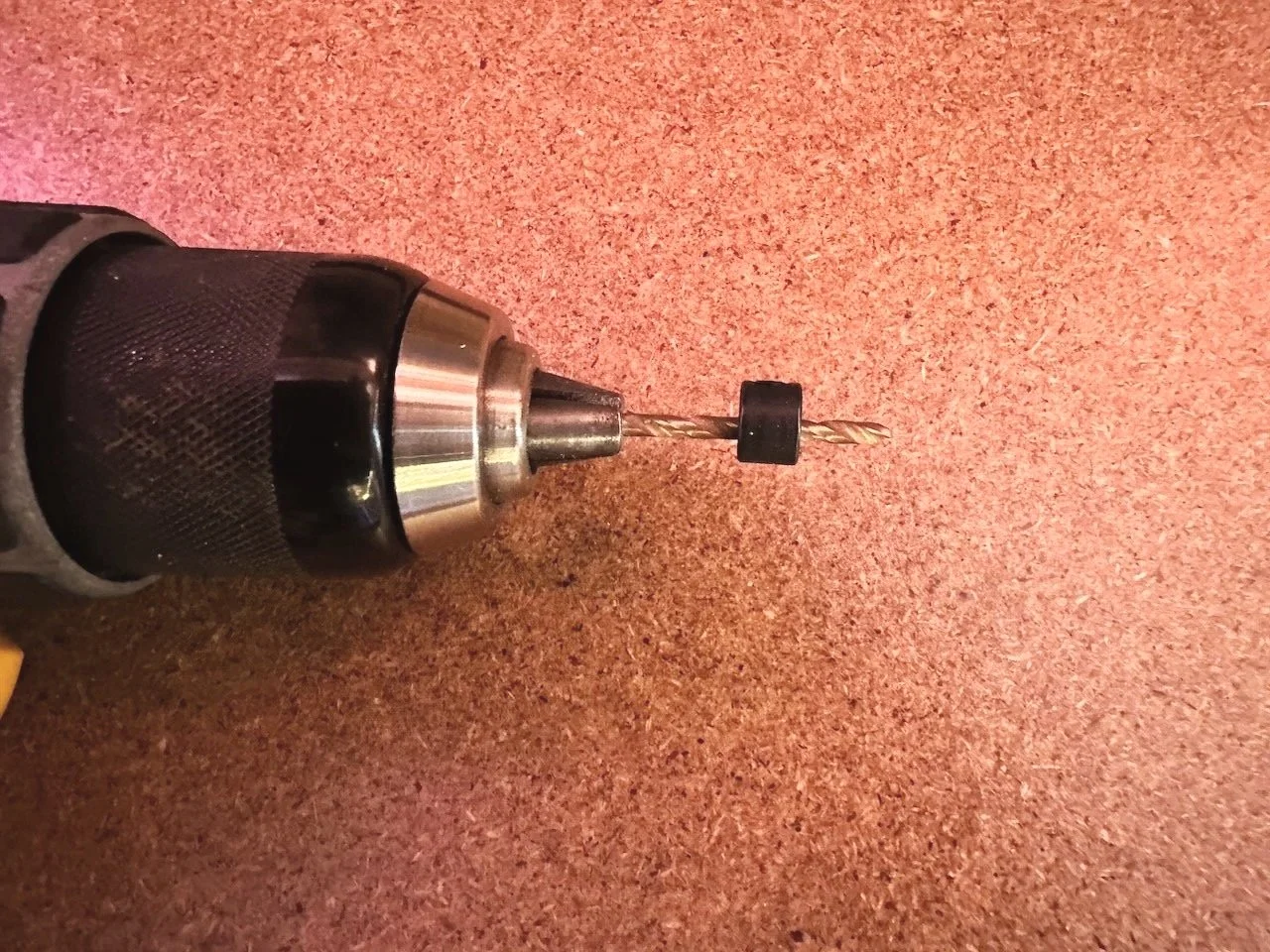

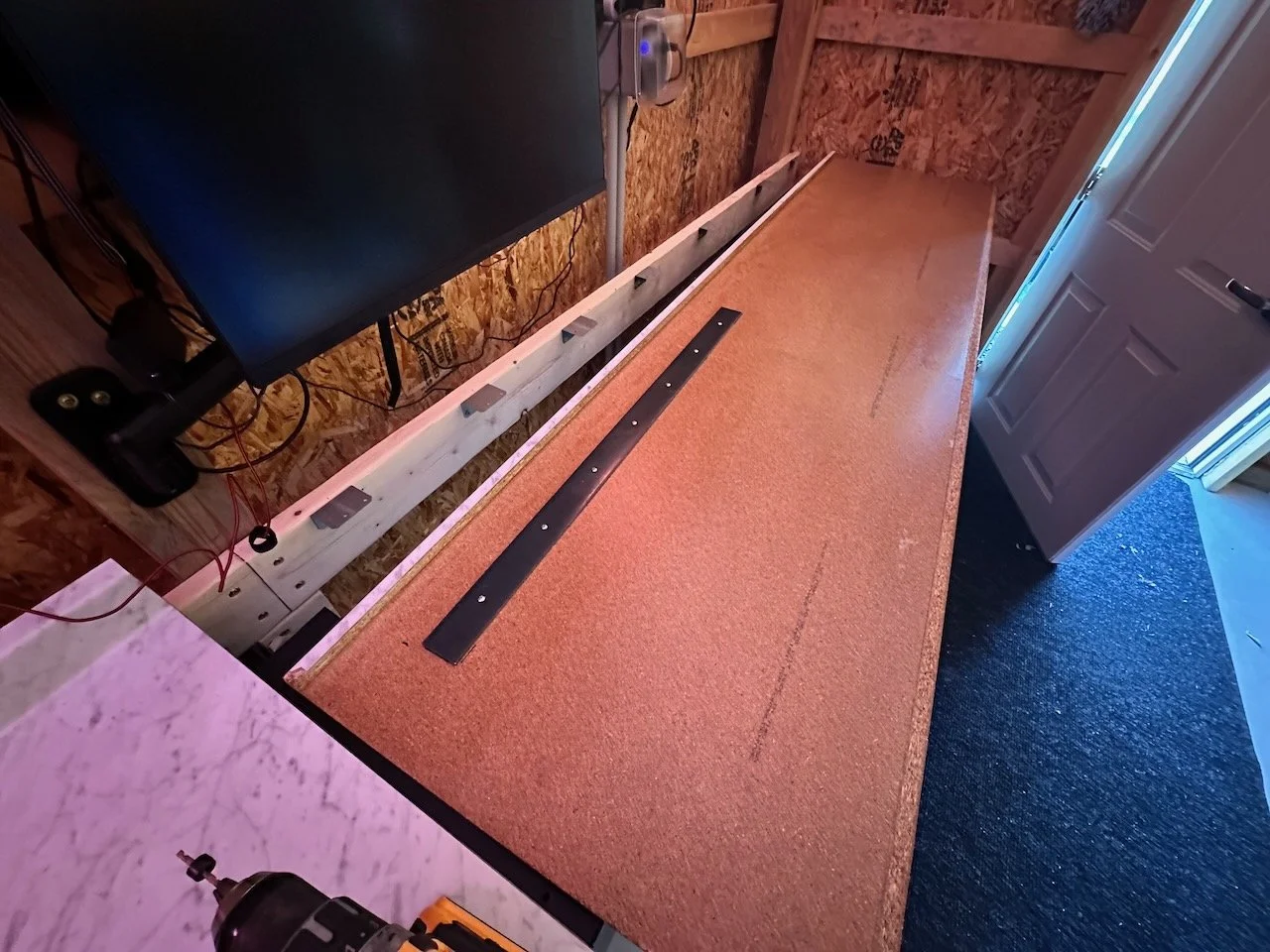

I also flipped the countertop section upside down. I took a 2 x 36 x 1/8-inch steel bar, drilled holes in it, and screwed it into the bottom of the particleboard, a few inches back from the front. I drilled a smaller pilot hole in the particleboard for the screws. I used a drill stop collar to ensure that these pilot holes did not get to close to the formica top.

The steel bar - with holes already drilled, is on position where I want it. I used a marker to mark the hole position and punch to better mark the hole positions.

The pilot holes are now drilled.

The drill stop collar on the pilot hole drill.

The bar is now secured into place.

Cutting the countertop to length is tricky because the profile is a 'Z' shape. But a few YouTube videos taught me the best way to do this. So after taping up the cut zone, clamping some scrap wood guides, and putting a finer-toothed saw blade on my circular saw, I went to work.

The cut went smoothly and I was ready to proceed.

Taped and clamped for the cut.

The cut is made!

A view from the other side of the counter showing the block guide for the backsplash.

Another view.

I used waterproof wood glue diluted 1:1 with water to brush on the fresh cut end. This will seal things nicely.

The cut worked out just fine, but led to a raw edge that was no longer sealed. I read a tip about this and used exterior wood glue mixed 50-50 with water and painted it onto the edge.

The final countertop can now be installed.

I originally had the computer monitor mounted on a pneumatic arm attached to the east side of the center post. This would no longer work with the countertops in place due to

the backsplash, so I remounted it on the face of the post, slightly higher. This looked like it would work well. The monitor could be positioned over the knee hole and clear the wall cabinets, while I could pull it out and orient it toward the various piers as needed.

The repositioned pneumatic arm for the computer monitor.

The second countertop in place and the base is dry-fitted in place. Looking good!

At some point, I needed to secure all of this.

I needed to bolt the cabinets together with four stainless-steel bolts and screw the countertops to the ledger boards and angle irons, then run the screws through the cabinets. This would be a lot of work down low, and with my knees and back, it just wasn't going to happen. My younger son, Kevin, offered to do this part when he visited during Thanksgiving.

Wall Cabinets

The wall cabinets were light enough for me to do myself.

They were designed to hang from twin cleats on a steel J-channel mounted on the wall. But with the Pole-Barn method of construction, all I had was a series of horizontal running 2x4s to use for this.

In general, I wasn't expecting to put much weight on the wall cabinets. So what I finally decided to do was to put sheets of 3/4-inch plywood - the same width as cabinets and 48 inches tall. These were positioned where I needed to place cabinets and screwed into the horizontal 2x4s with some GRKs.

3/4-inch plywood sections. Each piece is as wide as the cabinet (28”) and 48” tall. These are just standing on the countertop to check the placement,.

First two wall cabinets are in place.

Third cabinet installed.

The first plywood section is secured into place, and the steel j-channel is installed. The cabinet is ready for installation.

The final two plywood pieces are in place.

All four in place!

The outer two wall cabinets had to be moved inward. The west side had to be moved in to avoid the motor mounting plate. The eastern cabinet, because I forgot I needed some clearance for the Roof Lock down on that corner.

After that, I had to mount the steel J-channel at the right height, and then the cabinets were just hooked on.

Locking Everything Down

After Thanksgiving, my son Kevin and I set out to lock everything down. This involved Kevin crawling around on the floor doing the work while I cheered him on. Just watching him work tired me out!

First, we removed the doors from the two-door base units, then the four drawers from the drawer base units. We (i.e., Kevin) bolted the cabinets together with four stainless steel bolts, lock-nuts, and nuts.

Then we had to figure out how to handle the countertops. First, we laid out the sill sealer again to provide a cushion against vibration between the metal cabinet tops and the countertops.

Then, we would bolt up through each cabinet, so that part was easy.

But the ledger board was a different story. Some of these angle irons were reachable, and we could screw things right in. But some were not. For those, we put a small dab of construction adhesive on the metal angle iron. The countertops were put into place and screwed down. We also added some small angle irons to the knee hole areas on the side. These were screwed in with self-drilling metal screws.

Kevin hard at work.

Getting ready to do the west side countertop.

Drawers and doors off. Sill seals laid out.

Bolting things into place.

Installing the small angle irons in the knee hole area.

A view under the knee hole. You can see the iron plate, the and angle on the sides of the cabinets and at the back on the ledger board.

Under Cabinet Lighting

Finally, I ordered undercabinet LED lights, and we mounted them beneath the cabinets. I ended up with a bunch of cables for all this, so I screwed some narrow plywood to the bottom of the ledger board, facing in toward the outer wall. This provided a convenient shelf below the countertop backsplash, a nice place to hide power strips and extension cords.

Installing the under cabinet lighting

West side now done!

All done!

Another view.

Loading Things In

I can now move all of my ‘stuff’ into this new storage area! Everything fits with still space for future use and expansion! I am still playing with how I am organizing this space, but I am really happy with the final result!

One Gotcha!

I did discover one issue. With everything dry-fitted, all the doors and drawers worked smoothly. However, once I bolted the cabinets together, I found that two of the doors on the outer base cabinets were binding slightly when opened. Looks like it really needed another 1/8-inchof space between the two cabinets. The next time Kevin comes up, we will adjust and correct things.

Yet to be Done

I wanted something to dress up the back wall between the wall cabinets or the area above the countertop. I think I am going to paint the pegboard gray and use that to dress up this area. The pegboard is inexpensive, easy to seal, and will ventilate the spaces behind it. This last part is important since there is no insulation in the building.

Since it is too cold to paint right now, I will put this task off until spring and warmer weather. I wanted to create a picture display wall on the Northwest side, but that will have to wait until warmer weather for the same reasons.